Proof of effectiveness in hopsitals

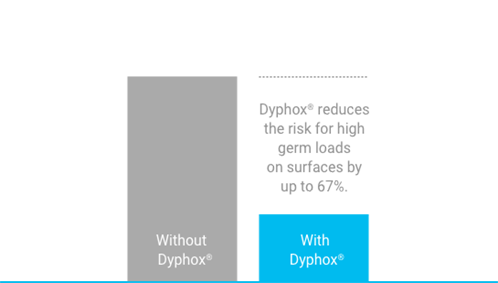

The DYPHOX coatings were tested for the first time in a large-scale field study in two hospitals in Regensburg, Germany. As part of the study, various surfaces were treated either with an active antimicrobial coating or a control coating. Over several months, the number of bacteria on the active and control surfaces was determined and compared. Meanwhile, everyday clinical operations continued, and routine cleaning and disinfection of the surfaces were carried out unchanged according to the hygiene plan.

Ultimately, the evaluation provided a clear result. The DYPHOX coatings were able to reduce the risk of high germ contamination on surfaces by up to 67%. The results of this field study were recently published in the internationally renowned Journal of Hospital Infection.

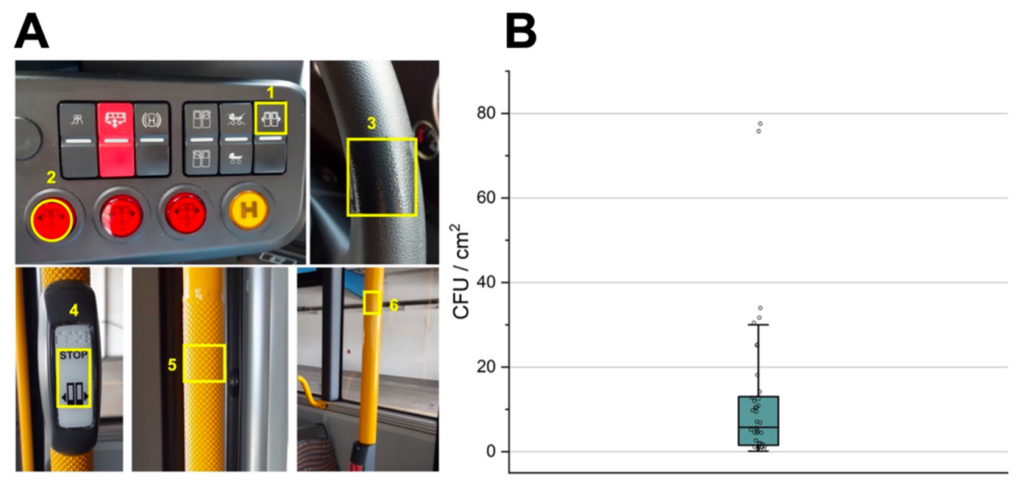

Proof of effectiveness in public transport

In February of this year, an independent study in Regensburg buses was published in the internationally recognized International Journal of Environmental Research and Public Health, which was able to show that the antimicrobial coating DYPHOX keeps the microbial load on high-contact surfaces low and reduces the risk of microorganism transmission. DYPHOX thus contributes permanently and proactively to a reduction in the number of germs on surfaces in public transport and closes hygiene gaps in the process.

DYPHOX was founded in 2010 as a spin-off of the University Hospital Regensburg. Ten years of research and development made it possible to bring highly effective surface coating and additive products to the market.

DYPHOX Protection – the antimircobial retrofit coating

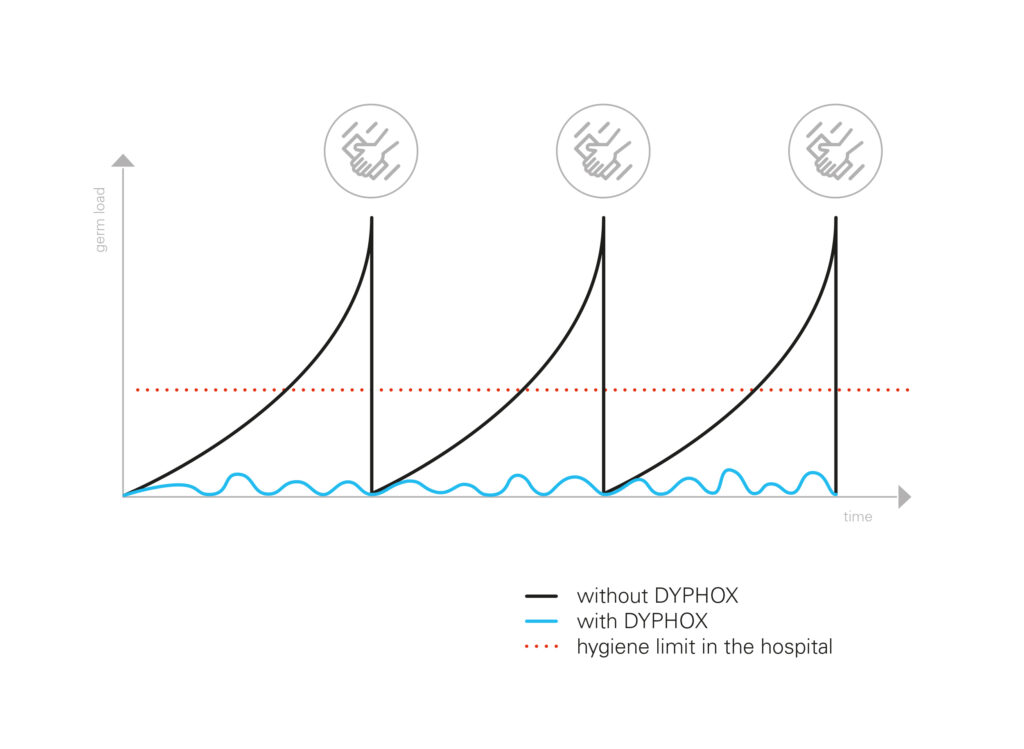

With DYPHOX Protection, we are currently offering an effective and safe hygiene solution for frequently touched surfaces both in professional hospital hygiene and in public areas (e.g. public transport, industry, office environments, hotels, supermarkets). The colorless, retroactively wipeable coating permanently closes hygiene gaps and thus better protects patients, customers and employees. The unique active principle ensures consistent effectiveness on dry and moist surfaces. This makes DYPHOX Universal the only antimicrobial surface coating that is proven to be effective under real conditions..

Which materials are suitable?

How it is applied?

You want to know more details? Get more detailed information about DYPHOX Protection.

DYPHOX Solution – additives for treating industrial products with an antimicrobial coating

In addition to DYPHOX Protection, we also offer with DYPHOX Solution additives for the antimicrobial treatment of industrial products. This protects your product and minimises the transmission of germs. We develop individual solutions with our customers and support them with consulting and other services.

Which products are suitable?

You want to know more details? Get more detailed information about DYPHOX Solution.

What are the benefits of DYPHOX?

Bactericidal

Virucidal

No resistance build-up

Clinically tested

Effective on dry surfaces

Permanent and long-lasting effect

Reliable

Avoidance of toxic biocides and nanoparticles

Material protection

Prevents odours

Material protection

Risk reduction

Easy and efficient disinfection – close the hygiene gaps.

In hospitals and nursing homes, standard operating procedures (SOPs) and hygiene plans ensure regular cleaning and disinfection of surfaces in close proximity to patients. However, manual disinfection by wiping is only effective for a certain time frame. Recontamination between disinfection cycles is hard to prevent. The permanently effective, antimicrobial DYPHOX Universal retrofit coating makes it possible to close the hygiene gaps. It has been proven to reduce the risk of high bacterial loads by up to 67% and thus also the risk of spreading germs via surfaces.

Sources:

Eichner et al., Novel photodynamic coatings reduce the bioburden on near-patient surface thereby reducing the risk for onward pathogen transmission – a field study in two hospitals. Journal of Hospital Infection, 2019. 104(1): 85–91.

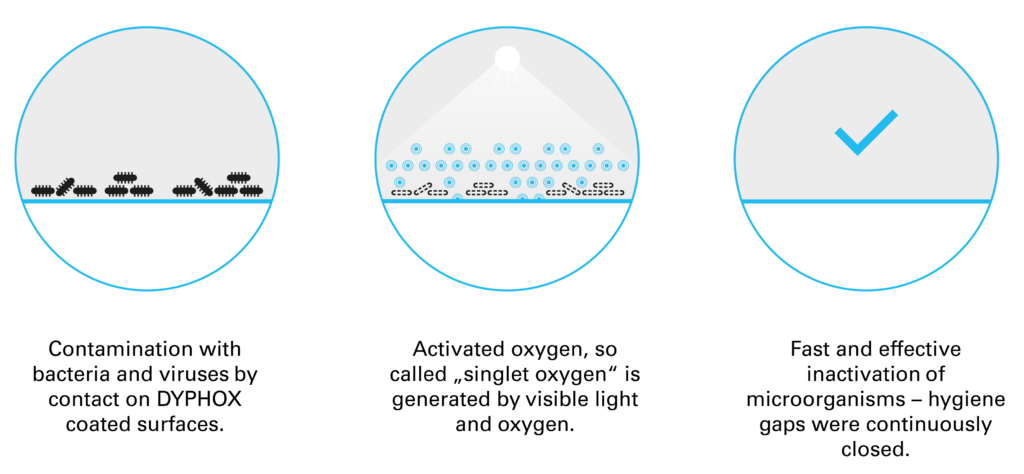

DYPHOX technology: Photodynamics